Our facilities

TECHNOLOGY

QUALITY

Our facilities

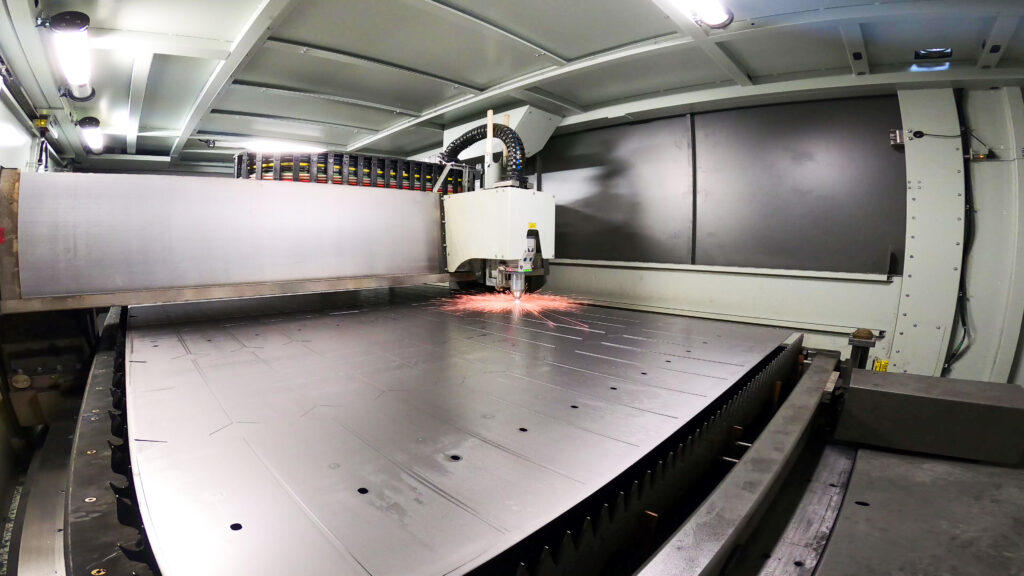

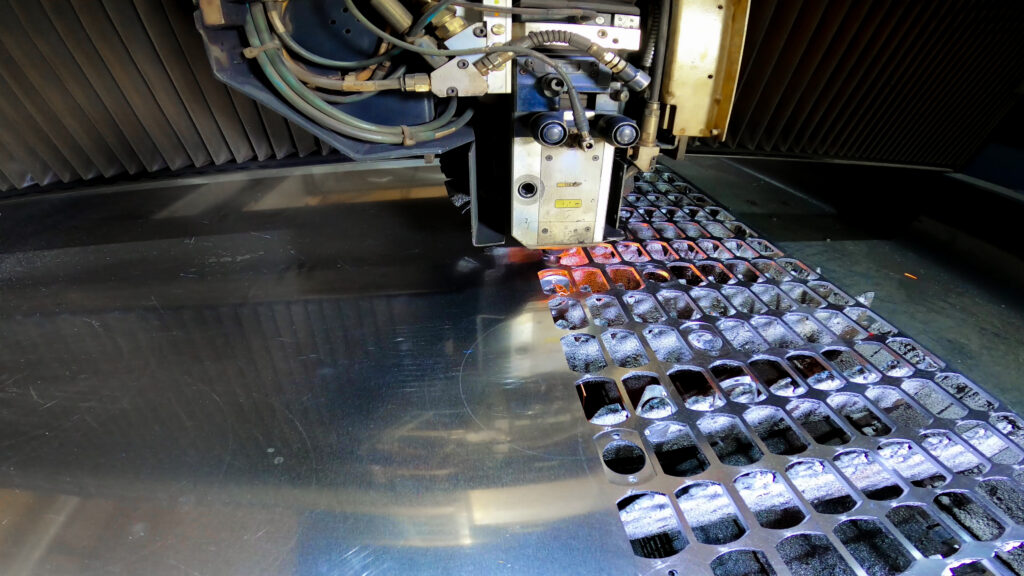

Our company not only broadens knowledge in the field of metal processing but also invests in modern machines and technologies that help to improve work, which translates into quality and precision in the production process and the time of tasks performed. Below we present the equipment we use in the production process.

In addition, we have a well-equipped tool room with a universal lathe.

Below are the parameters of the machine on which we work.

- Laser power 2 kW

- Maximum working area 3000 x 1500 mm

- Cutting thickness range

- Black steel – 12 mm

- Stainless steel – 6 mm

- Aluminum – 6 mm

- Brass – 4 mm

- Copper – 3 mm

- 5 kW laser power

- Maximum working area 3000 x 1500 mm

- Cutting thickness range

- Black steel – 25 mm

- Stainless steel – 15 mm

- Aluminum – 10 mm

- Laser cutting of pipes with a diameter of 20 to 210 mm with a maximum length of up to 6000 mm

- Laser cutting of profiles with a wall width from 20 mm to 150 mm and a length of up to 6000 mm,

Maximum cutting thickness:

– Steel – 6mm

– INOX – 4mm

– Aluminum – 3mm

– Copper – 2mm

- Laser cutting of pipes with a diameter from 12 to 152.4 mm with a maximum length of up to 6500 mm.

- Laser cutting of profiles with a wall width from 12 mm to 152.4 mm with a length of up to 6500 mm,

The laser also enables cutting of sections; open profiles and special profiles.

Maximum material weight: 23 kg / m.

- Three metal cutting stations, including a band saw

- Pegas 300 × 320 shi-lr

- Maximum cutting length – 2000mm

- Maximum cutting thickness – 3mm

- The maximum bending length is 3000 mm

- The maximum thickness of bending over a length of 1000mm – 5mm

- Pressure – 125 tons

In our machine park, we have two LVD hydraulic press brakes that enable sheet bending at a length of 3000 mm. Press brakes are fully numerically controlled in 8 axes, which allows for the production of even very complex elements.

– Pressure 135 T

– Maximum thickness of bending over a length of 1000mm – 8mm

Laser head for cutting material at an angle – 3D

- Cross section Ø 54 x 3 mm

- Maximum bending angle 180 degrees

Pipe processing parameters:

20 x 1.5 mm (rollable)

21.3 x 2 mm (rollable)

33.7 x 2 mm (rollable)

42.4 x 2 mm (rollable)

42.4 x 3.2 mm (rollable)

48.3 x 2 mm

60.3 x 2 mm

Profile processing parameters:

40 x 40 x 2 mm

30 x 30 x 1.5 (rollable)

40 x 20 x 1.5 (rollable)

- The maximum thickness of the elements to be welded is 5mm + 5mm

Power source 350A, Arm reach 2011 mm

Dimensions of the working place 2500 x 1200

- Five welding stations with a work table of 3000 × 1500

- Two welding stations with a work table of 2000 × 1000

- 7 MIG / MAG welding machines

- 2 TIG welders

We have two furnaces for burning elements with dimensions:

– 1650x4400x1900

– 1350x3400x1900

We use a manual applicator to apply Wagner powder paints.

- Four assembly stands with a total area of 400 m2

- Laser power 2 kW

- Maximum working area 3000 x 1500 mm

- Cutting thickness range

- Black steel – 12 mm

- Stainless steel – 6 mm

- Aluminum – 6 mm

- Brass – 4 mm

- Copper – 3 mm

- 5 kW laser power

- Maximum working area 3000 x 1500 mm

- Cutting thickness range

- Black steel – 25 mm

- Stainless steel – 15 mm

- Aluminum – 10 mm

- Laser cutting of pipes with a diameter of 20 to 210 mm with a maximum length of up to 6000 mm

- Laser cutting of profiles with a wall width from 20 mm to 150 mm and a length of up to 6000 mm,

Maximum cutting thickness:

– Steel – 6mm

– INOX – 4mm

– Aluminum – 3mm

– Copper – 2mm

- Laser cutting of pipes with a diameter from 12 to 152.4 mm with a maximum length of up to 6500 mm.

- Laser cutting of profiles with a wall width from 12 mm to 152.4 mm with a length of up to 6500 mm,

The laser also enables cutting of sections; open profiles and special profiles.

Maximum material weight: 23 kg / m.

- Three metal cutting stations, including a band saw

- Pegas 300 × 320 shi-lr

- Maximum cutting length – 2000mm

- Maximum cutting thickness – 3mm

- The maximum bending length is 3000 mm

- The maximum thickness of bending over a length of 1000mm – 5mm

- Pressure – 125 tons

In our machine park, we have two LVD hydraulic press brakes that enable sheet bending at a length of 3000 mm. Press brakes are fully numerically controlled in 8 axes, which allows for the production of even very complex elements.

– Pressure 135 T

– Maximum thickness of bending over a length of 1000mm – 8mm

Laser head for cutting material at an angle – 3D

- Cross section Ø 54 x 3 mm

- Maximum bending angle 180 degrees

Pipe processing parameters:

20 x 1.5 mm (rollable)

21.3 x 2 mm (rollable)

33.7 x 2 mm (rollable)

42.4 x 2 mm (rollable)

42.4 x 3.2 mm (rollable)

48.3 x 2 mm

60.3 x 2 mm

Profile processing parameters:

40 x 40 x 2 mm

30 x 30 x 1.5 (rollable)

40 x 20 x 1.5 (rollable)

- The maximum thickness of the elements to be welded is 5mm + 5mm

Power source 350A, Arm reach 2011 mm

Dimensions of the working place 2500 x 1200

- Five welding stations with a work table of 3000 × 1500

- Two welding stations with a work table of 2000 × 1000

- 7 MIG / MAG welding machines

- 2 TIG welders

We have two furnaces for burning elements with dimensions:

– 1650x4400x1900

– 1350x3400x1900

We use a manual applicator to apply Wagner powder paints.

- Four assembly stands with a total area of 400 m2